MANN-FILTER กรอง ทุกชนิด จากยุโรป OEM รถยนต์ยุโรปป้ายแดง

MANN-FILTER

As a strong global filter brand MANN-FILTER offers a comprehensive range in 100 percent OE matching quality and provides excellent service performance for the automotive aftermarket.

The premium brand with its claim "Perfect parts. Perfect service." stands for innovative and high quality products, consistent customer orientation and an excellent distribution and marketing performance. With a market coverage of 98 percent for the European vehicle fleet, MANN‑FILTER has the most comprehensive range of filters in OE matching quality for the automotive aftermarket.

Furthermore, MANN‑FILTER is characterized by a wide range of products for agricultural and construction machinery and also industrial filtration. Around the world, 7,000 filter elements are available for more than 90,000 vehicles and machines.

1. Filter medium

The core of the filter

Clean combustion requires clean fuel. The job of the filter medium, the core of the filter, is to clean the fuel. Media expertise is our core expertise.

Filters are the silent heroes of automotive engineering. Hidden inside the vehicle the filter is not seen or heard by the occupants of the vehicle. Yet the filters provide continuous high performance. The core of each filter is the so-called filter medium. It does the main work, the cleaning of the fuel. This is because without clean fuel, clean combustion is not possible.

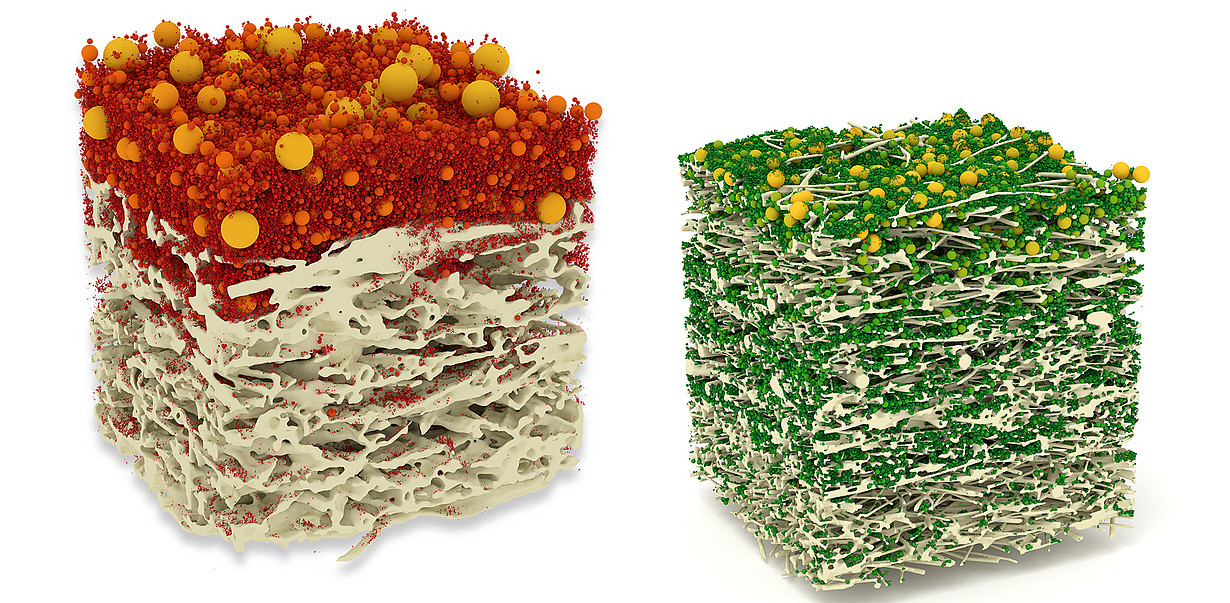

Three layers for high requirements

Modern injection systems with minute nozzles, high pressures of up to 2,500 bar and cycle times in the millisecond range are highly sensitive. Even the smallest dirt particles in the fuel can have the effect of a projectile in such systems and cause substantial damage.

MANN+HUMMEL uses a triple layer filter medium to meet this challenge. The first layer is a fully synthetic fiber layer. It enables an increase in the dirt holding capacity. The second layer is made from a combination of cellulose and ultra-fine glass fibers. It ensures a high separation efficiency to maximize the number of particles the filter can retain. A final cellulose layer with a support function prevents the escape of glass fibers.

New development from the test bench

After the definition of different parameters, each new development is set up on the test bench. That starts with a first sample of the filter medium in DIN A4 size. Using computers, the developers at MANN+HUMMEL are able to determine how many particles are held back by the filter medium. Using modern filter media, for example, only 3 of every 1,000 particles in the flow with a size of 4 micrometers are able to reach the other side of the filter. These particles are up to 18 times finer than a human hair.

In the next step the medium has to prove that, despite many arrested dirt particles, it will not clog prematurely. The developers examine the so-called dust holding capacity and for this purpose add soot particles to the filter on the test bench. This enables the researchers to get closer to real operating conditions and make very exact predictions as to how the filter medium will function under actual operation.

Filter medium manually crafted

Low volume tests are conducted in a suitable production plant. Here processing specialists and technicians work on the fine-tuning of the filter medium and details such as the use of suitable technology to join the filter medium to the end cap. 20 to 30 sample filters are made this way manually. Then the filters return to the test bench. If the results are not satisfactory, the materials and processing are adjusted, and further tests are carried out.

Step by step to the end result

In the last step the filter returns to the production plant, where high volume tests are conducted. Machines with huge rollers process roughly a tonne of the new filter medium, and several hundred filter elements are manufactured under series production conditions. With cutting, pleating, curing and other steps the new development has to prove that it will be able to handle non-stop processing and remain stable in the process. When this implementation is finally successful under series production conditions, the production plant and development department give the go-ahead, and a new filter medium is born.

To breathe freely inside your vehicle

·

More and more people nowadays suffer from allergies. To give these people protection, MANN+HUMMEL has developed a cabin filter which also adsorbs allergenic substances and at the same time prevents bacteria from entering the interior of the vehicle through the ventilation or air conditioning system.

For some years now, the World Health Organization has classified allergens as the fourth most common chronic illness worldwide. This is because more and more people today suffer from allergic reactions which means that their immune system is hypersensitive. This is no surprise as pollen, bacteria and mold fungi continue to further penetrate our everyday life, and also in the car. As well as being annoying and polluting the air inside the vehicle, this endangers road safety because if the driver suddenly has to sneeze he is distracted for about two seconds. The dangerous consequence is a restricted ability to react and a longer braking distance.

Hard work for filters

The protection of the driver and vehicle occupants against pollen and bacteria requires the use of effective cabin air filters. This is because during the pollen season there are roughly 3,000 types of pollen in just one milliliter of air. It sounds like a huge task for the filter. And that is just what it is.

MANN+HUMMEL has developed an efficient solution to tackle the problem. This is a cabin filter which adsorbs allergens in addition to small and coarse particles. The filter also prevents bacteria and mold fungi from entering the passenger compartment through the ventilation or air conditioning system.

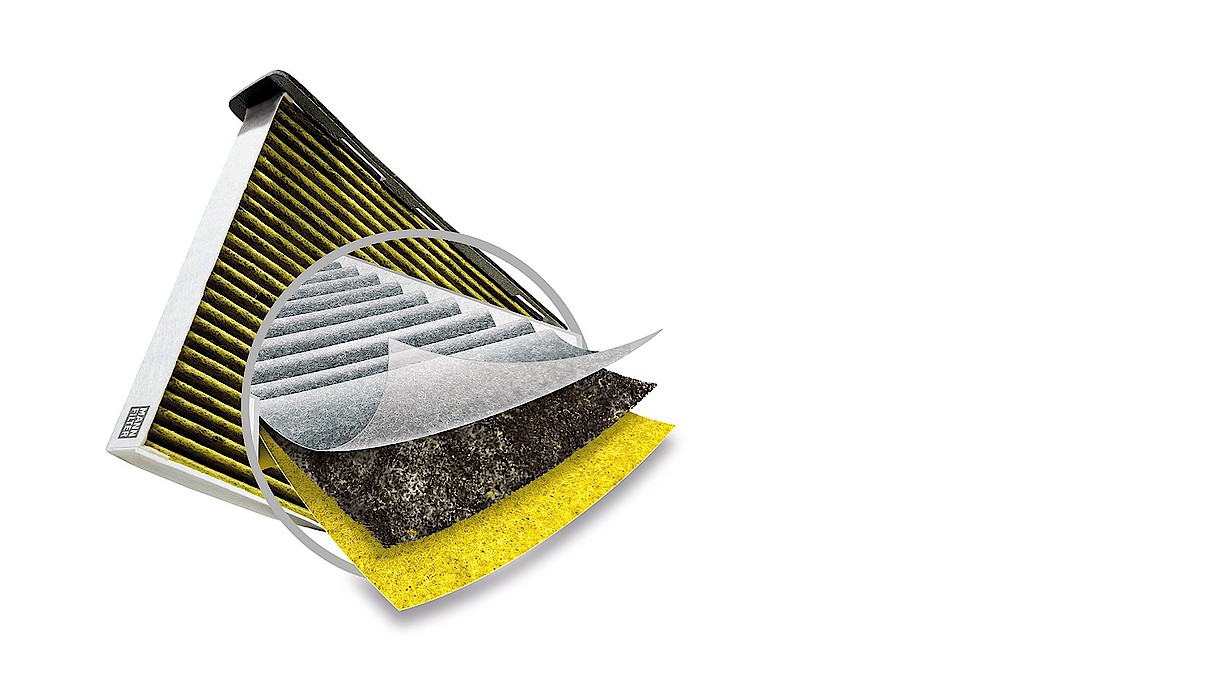

Biofunctional coating to protect against allergens

How does that work? Through the use of a very special filter layer.

Common cabin filters include a particulate filter and frequently also an activated carbon layer. This is also true for the cabin filters from MANN+HUMMEL. The particulate filter layer almost completely separates coarse particles such as dust, pollen and tire debris as well as the smallest, respirable particles such as particulate matter. The layer of activated carbon adsorbs harmful gases, unpleasant odors and ozone almost completely from the air flowing through the system.

But these cabin filters also have a third layer with a special biofunctional coating made from so-called polyphenols. Polyphenols are natural products with an anti-inflammatory effect and are perceived to promote good health. They are present in plants such as green tea and pomegranates and many others and have the ability to adsorb allergens and make them harmless. This mechanism is exploited by MANN+HUMMEL.

Three layers technology for comfort and safety

Nipping a disease early in the bud

The polyphenol coating has an antiallergenic and antimicrobial effect. It protects the driver and vehicle occupants against bacteria, mold fungi and allergens and adsorbs them by up to 100 percent. Growth of mold fungi will decrease by more than 95 percent. This allows us to nip diseases in the bud, and those suffering from allergies can breathe freely.

K.LOP AUTOMOTIVE PARTS อะไหล่รถยนต์-คอมแอร์รถยนต์ (ญี่ปุ่น-ยุโรป) สินค้าคุณภาพมีประกันบริษัท

K.LOP AUTOMOTIVE PARTS อะไหล่รถยนต์-คอมแอร์รถยนต์ (ญี่ปุ่น-ยุโรป) สินค้าคุณภาพมีประกันบริษัท

ธ.ไทยพาณิชย์

ธ.ไทยพาณิชย์

K.LOP AUTOMOTIVE PARTS อะไหล่รถยนต์-แอร์ รถญี่ปุ่น-ยุโรป ลูบริแคนท์สสำหรับเครื่องยนต์

E -mail: klopcoolstore@gmail.com

FACEBOOK: @klopyonstore

LINE@: @klopyonstore

LINE ธรรมดา:

อีเมล : klopcoolstore@gmail.com

TOP เลื่อนขึ้นบนสุด